Top 8 Green Manufacturing Trends for 2022

[ad_1]

The past two several years have resulted in a lot of improvements in just about every economic sector across the world. This is specially accurate for the producing market.

A lot of of the changes had now been applied before the start off of the pandemic. Many thanks to the pandemic, several of these are remaining applied to fantastic influence. These improvements have been kicked into superior gear thanks to elements such as instability in the source chain, substantial demand from customers for merchandise and modifying shopper wants.

Green Trends to Check out for in 2022

1. Clever electronic thread

Big manufacturers have adopted IoT and IIoT to kickstart smart manufacturing methods. These ‘digital threads’ play a key function in strengthening operational efficiencies, improve products high-quality and in flip brand loyalty. Businesses are now soliciting shopper inputs to enhance client encounter with innovations and style and design changes instructed by finish users. Developing in depth electronic threads will not only result in inexperienced manufacturing tactics but quality solutions as effectively. This is probable many thanks to secure digital system connectivity.

2. Sustainability

Producers are also shelling out close notice to sustainability as well. Sustainability through environmental, social and governance policies are no more time just watchwords. Companies are investing in scalable systems to strengthen their manufacturing approach to lower useful resource use even though creating considerably less waste.

3. More onshore production

To help save charges, sourcing supplies for manufacturing was outsourced to China and other nations. The pandemic has disrupted the source chain and there is no distinct plan when the source chain will be reset to the pre-pandemic degree. Employing materials manufactured in-region will develop extra careers and lower dependence on foreign resources though lessening shipping and delivery fees. This is going to just take precedence in 2022.

4. Shifting concentration from B2B structure to B2C

Manufacturers are now focusing more on B2C to give the stop buyer reduce priced goods and to manage model handle. Producers have plenty of components to target on with buyer working experience high-quality in mind.

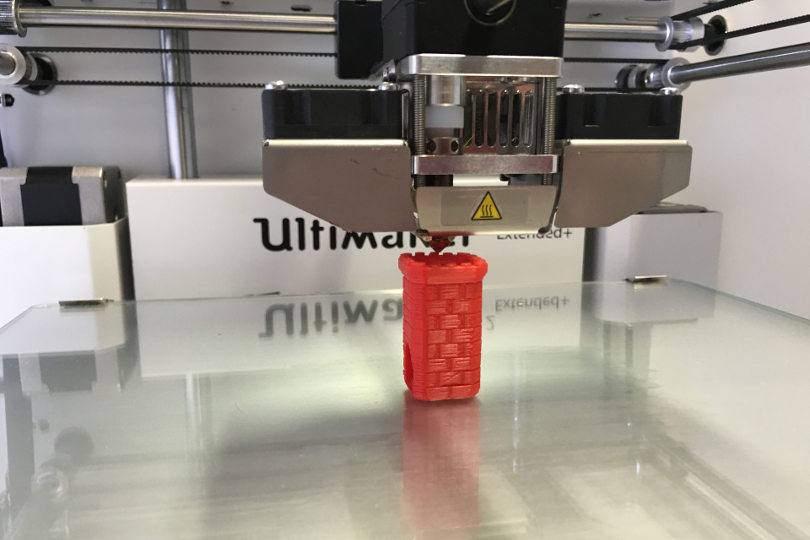

5. 3D Printing

Also known as additive manufacturing, 3D printing is heading to be a major thing in 2022. Some of the rewards available by this strategy are flexibility to style, custom made goods and solutions which carry out superior. This kind of production promotes inexpensive rates, sustainable procedure and most vital of all, a shorter time to current market. This process is getting actively made use of in the automotive and aerospace sectors.

6. Increased use of automation

Automation has been in use for a though in a few industries with PID controllers and PLCs. Wit the availability of rapid computer systems and many specialised software deals, automation has stepped in to fill the void from employee shortages. Automatic procedures are now in use not just on the manufacturing unit ground but also in the back again business. Know-how and wise machines are supporting with very good selection earning, product good quality and consistency.

7. Predictive routine maintenance

Technological know-how and automation are all over again filling a hole and doing away with guesswork. Predictive servicing systems track challenges and notify administrators of troubles in the producing system. Scheduled routine maintenance of machinery and pieces replacement is also performed so that there is incredibly minor downtime. This success in main costs discounts which can then be handed on to the stop person. Electronic transformation is the way to apply this and other such courses.

8. Office talent

The adoption of automation and other technologies in producing usually means that the workforce ought to be technologically competent. Tech weighty industries like automotive and aerospace will want entry to a expertise pool which is acquainted with latest practices. Quite a few organizations are doing the job with vocational schools so that they have the proper people on the position.

Conclusion

A lot of the adjust in production is pushed by customer input these times. End customers want to know how their merchandise ended up created and what elements were being used. With a spike in vitality and uncooked material expenses, companies will have to also offer with environmental and other rules.

People are driving the modify in the direction of sustainability and providers are having their social obligation severely. Fortuitously, engineering is helping to make a great deal of these choices and variations feasible. Manufacturers are keenly mindful of the connection involving their brand graphic, production methods and earnings.

Obtain to systems like AI, robotics and blockchain will essentially shift the way goods are made.

[ad_2]

Supply link